Benefits of Cold Forging Heat Sinks

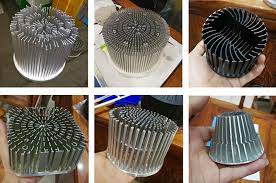

Improved surface finish. Better control of tolerance. Efficient use of raw materials. Reduced energy consumption.The heat sink adopts forging technology for integrated design and production, with low thermal resistance

and good heat conduction effect, which can effectively ensure the timely export of heat and achieve the ultimate heat dissipation effect. In addition, the cold forged heat sink has good mechanical properties, high

productivity and high material utilization rate, and is especially suitable for mass production, thereby reducing production costs.

What are the 4 steps of forging?

Forging is generally defined as the working of metal into a desired shape using compressive forces.

Heating. Pre-forged metal starts with metal blocks called "ingots," which come in a variety of shapes and sizes depending on the part or component to be produced. ...

Preforming. ...

Finish Forging. ...

Cooling. ...

Finishing According to the forging temperature, it can be divided into hot forging, warm forging and cold forging.According to the forming mechanism, forging can be divided into free forging, die forging, ring rolling and

special forging.

Dongguan Yihui Hydraulic Machinery Co., Ltd, is experienced in designing and manufacturing various types of hydraulic press machines and servo press, Such as cold forging press, hot forging press, powder

compacting hydraulic press, heating hydraulic press, deep drawing hydraulic press, servo press and so on . The plant is established in 1999 ,covers an area of 8,000 square meters. We are strictly implement the ISO9001 ,

CE, and SGS,BV management standards.

YIHUI brand presses have been exported to over 80 countries, Across five continents, in Europe, there are Germany, Italy, France, Sweden, Spain, Portugal, the United Kingdom, and so on. In the Americas, there are

the USA, Brazil, Chile, Argentina, and so on. In Asia, there are Japan, South Korea, Malaysia, Indonesia, Singapore, Thailand, Vietnam, etc. In Africa, there are South Africa, Algeria, etc. Hydraulic press machine and

servo press mainly applied to hardware, automotive, powder compacting,die casting, electronic, auto parts and other industries.

We can provide total solutions, including machines, molds, product processing technology, automated production lines

Post time: Jun-21-2023