Multidirectional (3D) forging press

Why Choose Us

YIHUI Hydraulic press with servo system,can bring you 10 kinds Advantages as below:

1.Can avoid the oil leakage. Because using Servo motor, the oil temperature can be lower.

2.English and customer country local language, bilingual operation interface, easy to operate.

3.Can save 50% – 70% electricity energy.

4.Parameters and Speed can be adjusted on the touch screen, easy to operate.

(Machine without servo system, speed can not been adjusted.)

5.Can be 3 to 5 years longer service life than the common machine.

It means,if common machine can service for 10 years, then machine with servo, can use 15 years.

6.Ensure safety and easy to know error,easy to do after service.

Because of Automatic alarm and auto troubleshooting system.

7.Very easy to change mold, shorter time of changing mold.

Because it have memory function,if use the original mold, do not need to adjust parameter again,

8.Very quiet , do not have noise.

9.Much stable than common machine.

10.Much high precision than common machine.

Products Description

1, Three-way multi-way forging press equipment adopts servo imported from Italy and Mitsubishi intelligent system control, intelligent operation is very high, strong stability.

2, the body of the solid steel plate after welding tempering treatment, using all directions of graphite copper guide guide, high compression precision, stable operation,

3, good rigidity, strong lateral force resistance, the cylinder adopts the whole forging process, Japan NOK seals, wear resistance and high sealing

Scope of application:

Multi-direction forging press is suitable for stretching, bending, forming, blanking, flanging and other stamping processes, especially for the following fields:

1. Auto parts: body covering parts pressing, brake sheet forming, oil tank stretching, chassis pressing, axle housing bending, bumper;

2. Household appliances: press assembly of washing machine parts, rice cooker parts, TV parts, refrigerator parts, etc.

3. Kitchen utensils: sink, kettle utensils, stainless steel utensils, other kinds of containers

4. Forging and forging forming process of bicycle, sports equipment, medical instruments, aluminum products and other tubular and shaped parts

Product Paramenters

Sample Product

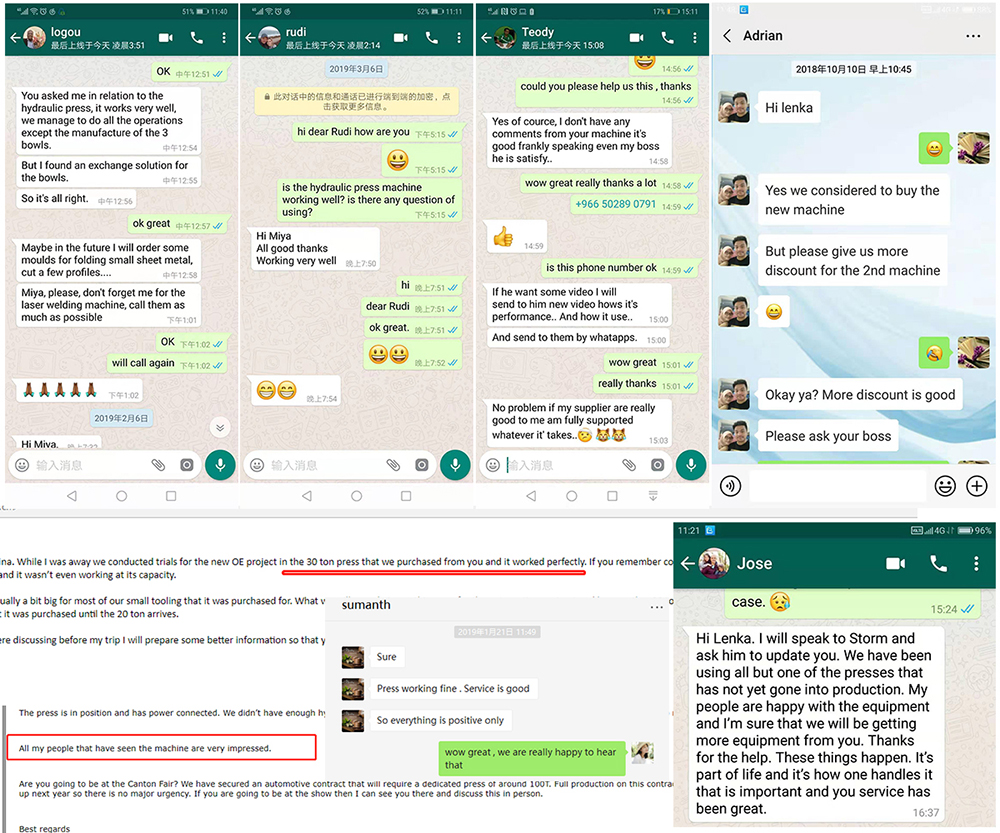

Why so many famous brand company cooperate with us ?

1.Our factory have specialized in independent development and producing hydraulic press for 19 years. So the product is stable and high quality.

2. Machine body, we use bending structure , much stronger than the common welding structure .

3. Oil pipe, we use Clip-on structure , much tight than common welding structure. Prevent oil leakage.

4. We take integrated oil manifold block, much easier to check machine and repair machine.

5.The main components are imported from Japan and Taiwan . So the quality is near the Japan production, but the unit price is lower than Japan production.

6.Our factory can offer full set line service, such as the mould,process technology, and other relative machines.

Certificate:

YIHUI Hydraulic press with servo system,can bring you 10 kinds advantages as below:

1.Can avoid the oil leakage. Because using Servo motor, the oil temperature can be lower.

2.English and customer country local language, bilingual operation interface, easy to operate.

3.Can save 50% – 70% electricity energy.

4.Parameters and Speed can be adjusted on the touch screen, easy to operate.

(Machine without servo system, speed can not been adjusted.)

5.Can be 3 to 5 years longer service life than the common machine.

It means,if common machine can service for 10 years, then machine with servo, can use 15 years.

6.Ensure safety and easy to know error,easy to do after service.

Because of Automatic alarm and auto troubleshooting system.

7.Very easy to change mold, shorter time of changing mold.

Because it have memory function,if use the original mold, do not need to adjust parameter again,

8.Very quiet , do not have noise.

9.Much stable than common machine.

10.Much high precision than common machine.