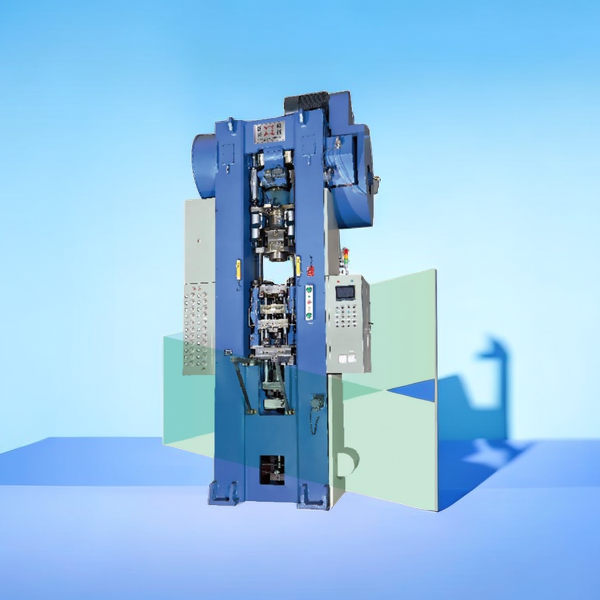

Fully automatic mechanical powder compacting press

Mechanical powder machine

Product Specifications

| Parameter name | 单位 | 规格 |

| Maximum pressing force | KN | 300 |

| Maximum modulus of force | KN | 180 |

| Maximum loading height | MM | 90 |

| Max out die stroke | MM | 60 |

| Upper slider stroke | MM | 125 |

| Upper slider adjustment range | MM | 50 |

| Forming times | N | 8-25 |

| More; less fill stroke | MM | 3 |

| Main motor power | KW | 5.5 |

| Final compression stroke | MM | 0-20 |

| Female die suface adjustment | MM | ±5 |

| Power Supply | 380V、3相50HZ | |

| Compressed air consumption | L/min | 55 |

| Negative template under pressure | KN | 150 |

| Double uprush inner punching capadily | KN | 150 |

| Double red outside the red bear | KN | 300 |

| A lower tolerance | KN | 300 |

| Two lower affordability | KN | 150 |

| A lower amount of adjustment | MM | 0-60 |

| Two undershoot adjustment | MM | 0-60 |

| Mandrel bearing force | KN | 150 |

| Punch fixing seat capacity | KN | 300 |

| A lower block adjustment | MM | 0-20 |

| Two lower block adjustment amount | MM | 0-20 |

| Weight of whole machine | T | 3.2 |

| Parameter name | unit | GX60T | GX100T |

| Maximum pressing force | KN | 600 | 1000 |

| Maximum modulus of force | KN | 300 | 500 |

| Maximum loading height | MM | 110 | 115 |

| Max out die stroke | MM | 65 | 70 |

| Upper slider stroke | MM | 160 | 160 |

| Upper slider adjustment range | MM | 80 | 80 |

| Forming times | N | 6-18 | 6-18 |

| More; less fill stroke | MM | 5 | 5 |

| Main motor power | KW | 7.5 | 15 |

| Final compression stroke | MM | 0-25 | 0-25 |

| Female die suface adjustment | MM | 士5 | ±5 |

| Power Supply | 380V、3相50HZ | 380V、3相50HZ | |

| Compressed air consumption | L/min | 80 | 120 |

| Negative template under pressure | KN | 300 | 500 |

| Double uprush inner punching capadiy | KN | 300 | 500 |

| Double red outside the red bear | KN | 600 | 1000 |

| A lower tolerance | KN | 600 | 1000 |

| Two lower affordability | KN | 300 | 500 |

| A lower amount of adjustment | MM | 0-80 | 0-80 |

| Two undershoot adjustment | MM | 0-80 | 0-80 |

| Mandrel bearing force | KN | 150 | 180 |

| Punch fiuing seat capacity | KN | 600 | 1000 |

| A lower block adjustment | MM | 0-20 | 0-20 |

| Two lower block adjustment amount | MM | 0-20 | 0-20 |

| Weight of whole machine | T | 7.5 | 12 |

| Parameter name | unit |

160T |

200T |

260T |

320T |

400T |

500T |

| Maximum pressing force | KN | 1600 | 2000 | 2600 | 3200 | 4000 | 5000 |

| Maximum modulus of force | KN | 800 | 1000 | 1300 | 1600 | 2000 | 2500 |

| Maximum loading height | MM | 150 | 150 | 150 | 150 | 150 | 150 |

| Max out die stroke | MM | 100 | 100 | 100 | 100 | 100 | 100 |

| Upper slider stroke | MM | 180 | 190 | 190 | 200 | 210 | 225 |

| Upper slider adjustment range | MM | 85 | 90 | 90 | 90 | 90 | 90 |

| Forming times | N | 6-18 | 5-15 | 5-15 | 5-15 | 5-15 | 5-15 |

| More; less fll stroke | MM | 8 | 8 | 8 | 8 | 8 | 8 |

| Main motor power | KW | 22 | 30 | 37 | 45 | 50 | 60 |

| Final compression stroke | MM | 0-40 | 0-40 | 0-40 | 0-40 | 0-40 | 0-40 |

| Female die suface adjustment | MM | ±8 | ±12 | ±12 | +12 | ±12 | ±12 |

| Power Supply | 380V、3相50HZ | ||||||

| Compressed air consumption | L/min | 130 | 150 | 180 | 250 | 300 | 360 |

| Negative template under pressure | KN | 800 | 1000 | 1300 | 1600 | 2000 | 2500 |

| Double uprush inner punching capadily | KN | 800 | 1000 | 1300 | 1600 | 2000 | 2500 |

| Double red outside the red bear | KN | 1600 | 2000 | 2600 | 3200 | 4000 | 5000 |

| A lower tolerance | KN | 1600 | 2000 | 2600 | 3200 | 4000 | 5000 |

| Two lower affordability | KN | 800 | 1000 | 1300 | 1600 | 2000 | 2500 |

| A lower amount of adjustment | MM | 0-100 | 0-85 | 0-85 | 0-110 | 0-110 | 0-110 |

| Two undershoot adjustment | MM | 0-100 | 0-85 | 0-85 | 0-110 | 0-110 | 0-110 |

| Mandrel bearing force | KN | 200 | 200 | 260 | 300 | 400 | 500 |

| Punch fixing seat capacity | KN | 1600 | 2000 | 2600 | 3200 | 4000 | 5000 |

| A lower block adjustment | MM | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 |

| Two lower block adjustment amount | MM | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 |

| Weight of whole machine | T | 18 | 26 | 30 | 38 | 45 | 55 |

Features:

●Adopt advanced computer touch screen operation, implement human-computer dialogue, and realize automatic adjustment of various functions. All adjustments are centrally controlled by the computer, which can store and recall process data of more than 100 products. Easy to operate and reduce labor intensity.

● Using a new C-type mold base (two upper, three lower), the inner and outer sides of the double upper punches can be mechanically adjusted, and the comprehensive filling mechanism performs filling to a certain extent, which can make up for the molding defects of complex or special-shaped pressed parts. (Special upper, three and lower four mold bases may be required)

● The comprehensive filling mechanism and pressing pressure adjustment device can maintain complex shapes and ensure the pressing effect. It implements initial pressure (upper punch insertion) and two-way pressing, upper punch pressurization and female mold floating (the female mold, first punch, and second lower punch can all float), and finally pressurized and ejected. And the parts are produced by the robot and the powder is automatically loaded.

● The mold ejection position and mold loading position are fixed.

Production parts

Production parts

Why so many famous brand company cooperate with us ?

1.Our factory have specialized in independent development and producing hydraulic press for 19 years. So the product is stable and high quality.

2. Machine body, we use bending structure , much stronger than the common welding structure .

3. Oil pipe, we use Clip-on structure , much tight than common welding structure. Prevent oil leakage.

4. We take integrated oil manifold block, much easier to check machine and repair machine.

5.The main components are imported from Japan and Taiwan . So the quality is near the Japan production, but the unit price is lower than Japan production.

6.Our factory can offer full set line service, such as the mould,process technology, and other relative machines.

Certificate:

YIHUI Hydraulic press with servo system,can bring you 10 kinds advantages as below:

1.Can avoid the oil leakage. Because using Servo motor, the oil temperature can be lower.

2.English and customer country local language, bilingual operation interface, easy to operate.

3.Can save 50% – 70% electricity energy.

4.Parameters and Speed can be adjusted on the touch screen, easy to operate.

(Machine without servo system, speed can not been adjusted.)

5.Can be 3 to 5 years longer service life than the common machine.

It means,if common machine can service for 10 years, then machine with servo, can use 15 years.

6.Ensure safety and easy to know error,easy to do after service.

Because of Automatic alarm and auto troubleshooting system.

7.Very easy to change mold, shorter time of changing mold.

Because it have memory function,if use the original mold, do not need to adjust parameter again,

8.Very quiet , do not have noise.

9.Much stable than common machine.

10.Much high precision than common machine.